Turbomolecular pumps for vacuum solutions.

·Intelligent design, excellent performance, compact size, powerful functionality.

·The complete turbo molecular pump product has a pumping speed ranging from 10 to 2,700 liters per second.

·Higher cost-performance ratio and flexible installation methods.

·High extraction speed is not affected by high load or the intrusion of impurity gases.

·Clean, environmentally friendly, and oil-free.

Applied to:

Photovoltaics, lighting, aerospace, semiconductors, energy, military industry, lasers, home appliances, materials, automobiles, scientific research, etc.

Company Name :

Shanghai Aifa Technology Co., Ltd.Brand :

AIFAFounded in 2009, Shanghai Aifa Technology Co., Ltd. is an enterprise integrating R&D, production, sales and after-sales service of dry vacuum pumps and vacuum solvent recovery systems, headquartered in Pudong New Area, Shanghai, the economic center.

The company has carried out in-depth cooperation with major domestic professional colleges and universities, professional chemical and pharmaceutical enterprises, and its products are jointly developed and designed with experts in chemical, pharmaceutical, environmental protection and other industries, and the equipment process, processing and manufacturing, performance and after-sales service are in the forefront of the domestic level.

1.DCP claw-type vacuum pump

Features:

① Verified through industry practice and proven over time.

② Specifically designed for chemical applications.

③ Carefully designed and tested to ensure safety and reliability.

④ Stable operation, even during process anomalies.

⑤ Low operating costs.

⑥ Easy to maintain, low power consumption, and does not require the injection of cooling gas.

2.VDP Screw Vacuum Pump

Features:

① Wide pumping speed range allows for direct atmospheric discharge, achieving the effect of multi-stage series operation with just a single pump.

② The single-stage design can achieve a vacuum level of 5 PA.

③ Nitrogen gas purging can be employed; cleaning and maintenance operations are simple, and repairs are convenient.

④ The screw is made of integral ductile iron, providing high strength and stable performance; the screws do not contact each other, eliminating friction, requiring no lubrication grease, preventing oil backflow, and eliminating waste gas and liquid discharge, making it clean, environmentally friendly, and energy-efficient.

⑤ The internal pump chamber and components can be surface-treated for corrosion resistance as needed, making it suitable for the special requirements of the chemical and pharmaceutical industries. 6. The screw undergoes precise dynamic balance correction, ensuring smooth operation, low noise, minimal vibration, and a long service life.

3.DRP Hydraulic Coupling Roots Pump

Features:

① The hydraulic transmission structure allows the Aifaluo Roots pump to start directly under atmospheric pressure or high differential pressure.

② The Roots pump can start and stop simultaneously with the primary pump. The Roots pump can automatically adjust its speed, preventing overload or overheating. Starting the Roots pump in advance under high differential pressure can reduce pumping time and improve the system's pumping efficiency.

③ In the event of foreign objects entering the pump chamber or sudden pressure changes, it automatically reduces speed for protection, resulting in an extremely low failure rate.

④ Simple configuration, no need for bypass pipelines, valves, or frequency converters, thus saving costs and facilitating convenient operation.

⑤ Operates smoothly and quietly, with minimal vibration, and the pump maintenance is straightforward.

Technical parameters

|

Model

|

Turbo-H160/800-FF

|

Turbo-H160/800-FFD

|

Turbo-H200/1400-FF

|

Turbo-H200/1400-FFD

|

|

Inlet Diameter

|

DN160 mm

|

DN200 mm

|

||

|

Exhaust Diameter

|

KF40 mm

|

KF40 mm

|

||

|

Pumping Speed

|

800 L/s

|

1400 L/s

|

||

|

Ultimate Pressure

|

5×10⁻⁷ Pa

|

|||

|

Maximum Fore-pressure

|

100 Pa

|

|||

|

For N₂

|

10⁸

|

|||

|

For H₂

|

1×10⁴

|

|||

|

Atmospheric Shock Resistance

|

Yes

|

|||

|

Motor Speed

|

24,000 r/min

|

|||

|

Start-up Time

|

<10 min

|

|||

|

Lubricating Oil Volume

|

260 mL

|

/

|

260 mL

|

/

|

|

Installation Position

|

Vertical

|

Any orientation

|

Vertical

|

Any orientation

|

|

Cooling Method

|

Water-cooled

|

|||

|

Cooling Water Consumption

|

90 L/h

|

|||

|

Cooling Water Temperature

|

<24°C

|

|||

|

Baking Temperature

|

100±10°C

|

|||

|

Model

|

Turbo - H250/2000 - FF

|

Turbo - H250/2000 - FFD

|

Turbo - H400/4000 - FFD

|

Turbo - H320/3201 - FFD

|

Turbo - H400/4301 - FFD

|

|

Inlet Diameter

|

DN250mm

|

DN400mm

|

DN320mm

|

DN400mm/VG350mm

|

|

|

Exhaust Diameter

|

KF40mm

|

KF40mm

|

|||

|

Pumping Speed

|

2000L/S

|

4000L/S

|

3400L/S

|

4500L/S

|

|

|

Ultimate Pressure

|

5×10⁻⁷Pa

|

||||

|

Maximum Fore-pressure

|

100Pa

|

||||

|

For N₂

|

10⁸

|

||||

|

For H₂

|

1×10⁴

|

||||

|

Can Withstand Atmospheric Pressure

|

Yes

|

/

|

|||

|

Motor Speed

|

24000r/min

|

18000r/min

|

24000r/min

|

||

|

Start-up Time

|

<10min

|

<20min

|

|||

|

Lubricating Oil Quantity

|

260ml

|

/

|

260ml

|

/

|

|

|

Installation Position

|

Vertical

|

Any

|

Vertical

|

Any

|

|

|

Cooling Method

|

Water-cooled

|

Air-cooled

|

|||

|

Cooling Water Consumption

|

90L/h

|

/

|

|||

|

Cooling Water Temperature

|

<24℃

|

/

|

|||

|

Baking Temperature

|

100±10℃

|

/

|

|||

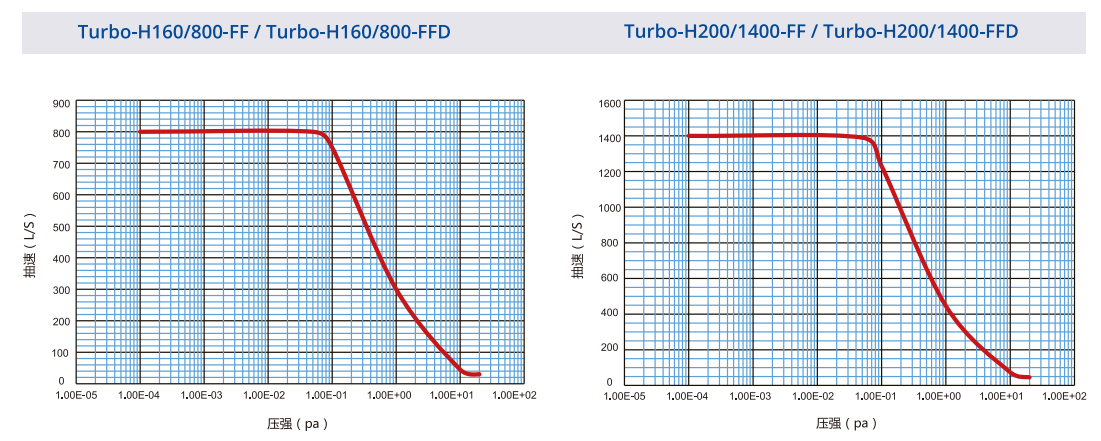

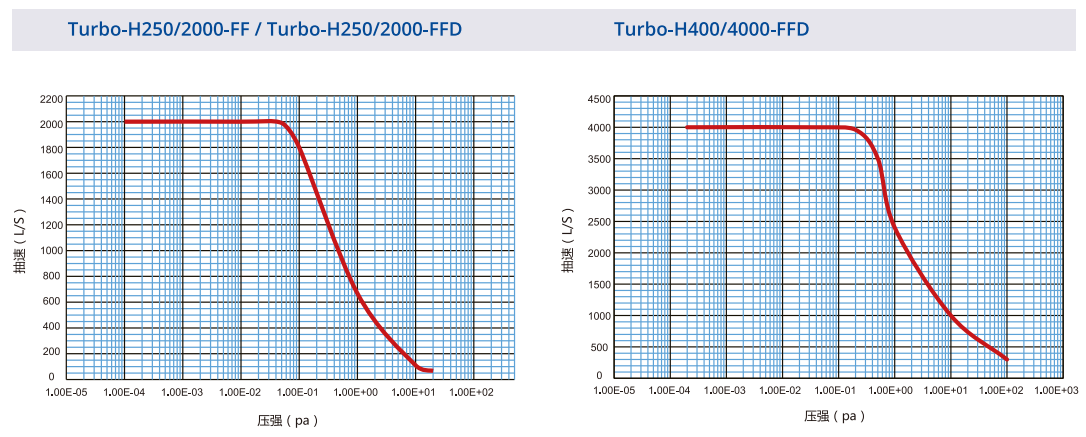

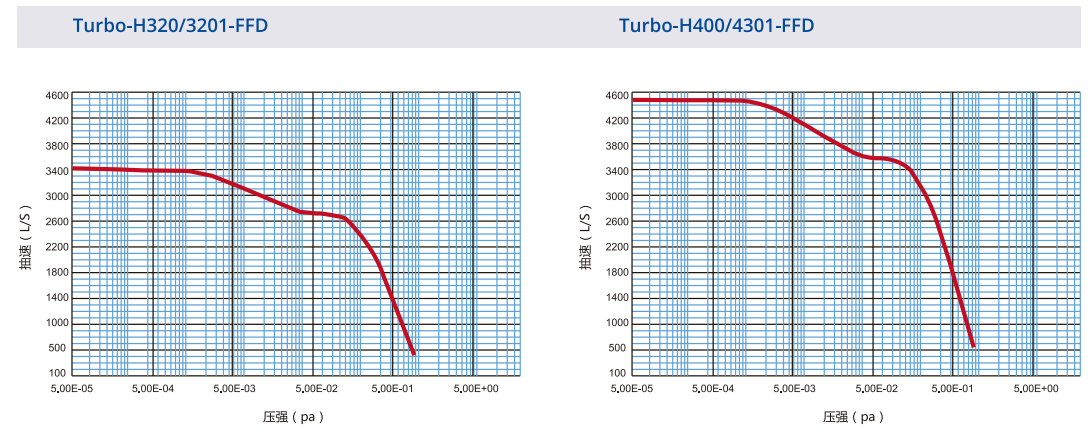

Pumping speed graph

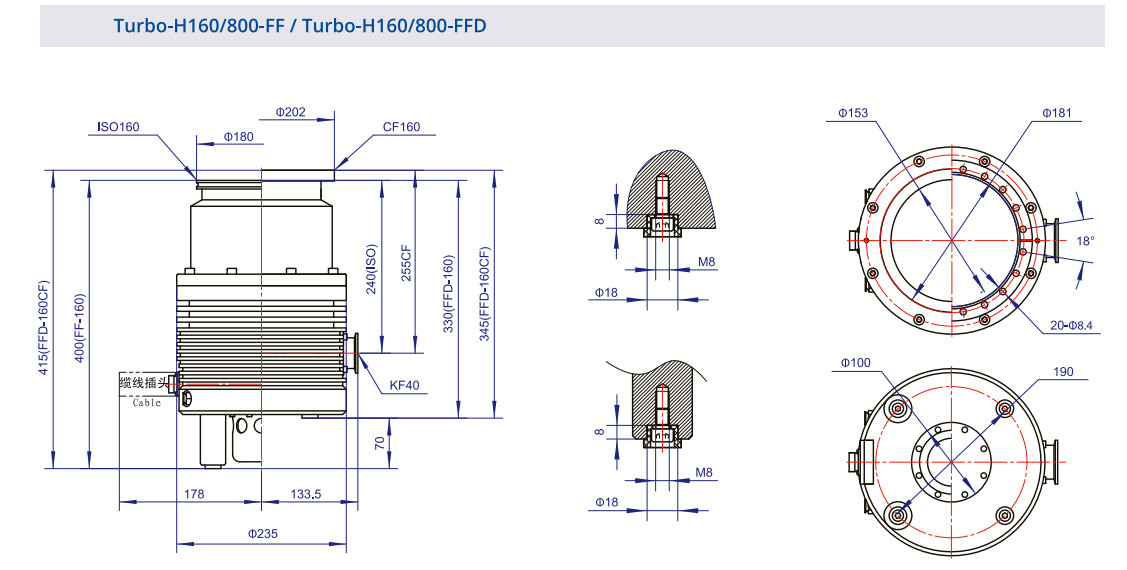

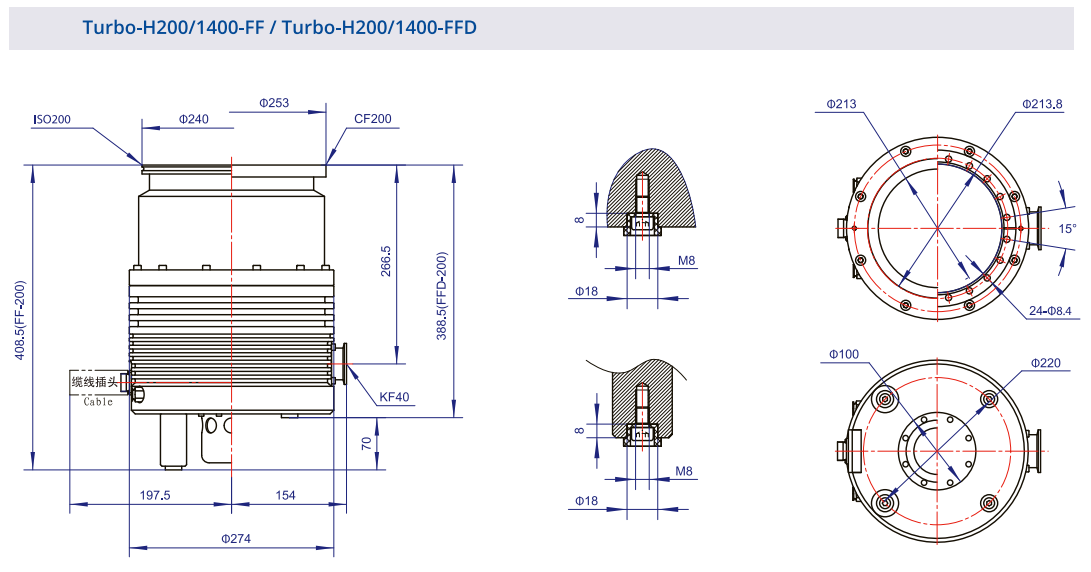

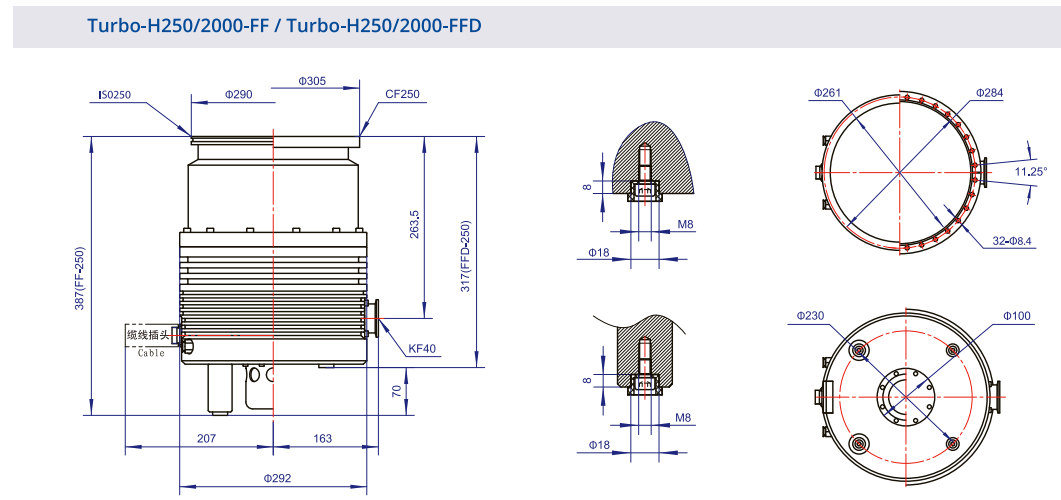

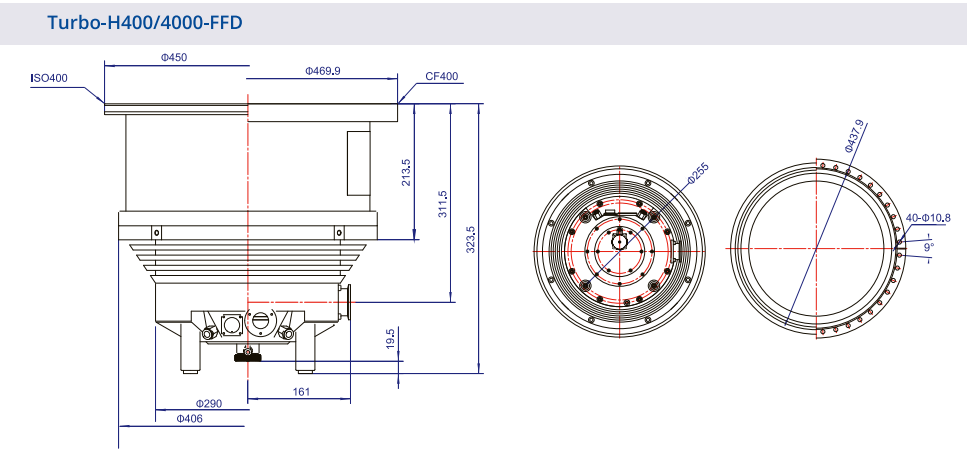

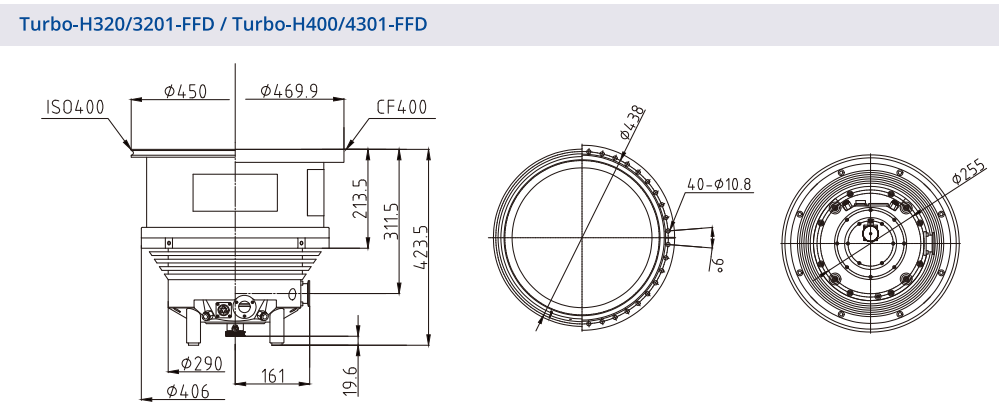

Dimensional installation drawing