The Highest Torque Pilot/Small-Scale Production System

Company Name :

Pharmaceutical Processing Solution Co., Ltd.Brand :

ppsPharmaceutical Processing Solution Co., Ltd. (PPS) is a high-tech company specializing in complete solutions for pharmaceutical hot melt extrusion and continuous granulation. Founded by Dr. Gaopin Yang, who has over 20 years of experience in academia and Fortune 500 company, GE&DuPont. PPS offers comprehensive hot melt extrusion and continuous granulation solutions, including equipment, processes, and custom services. Our goal is to become an industry leader and standard setter!

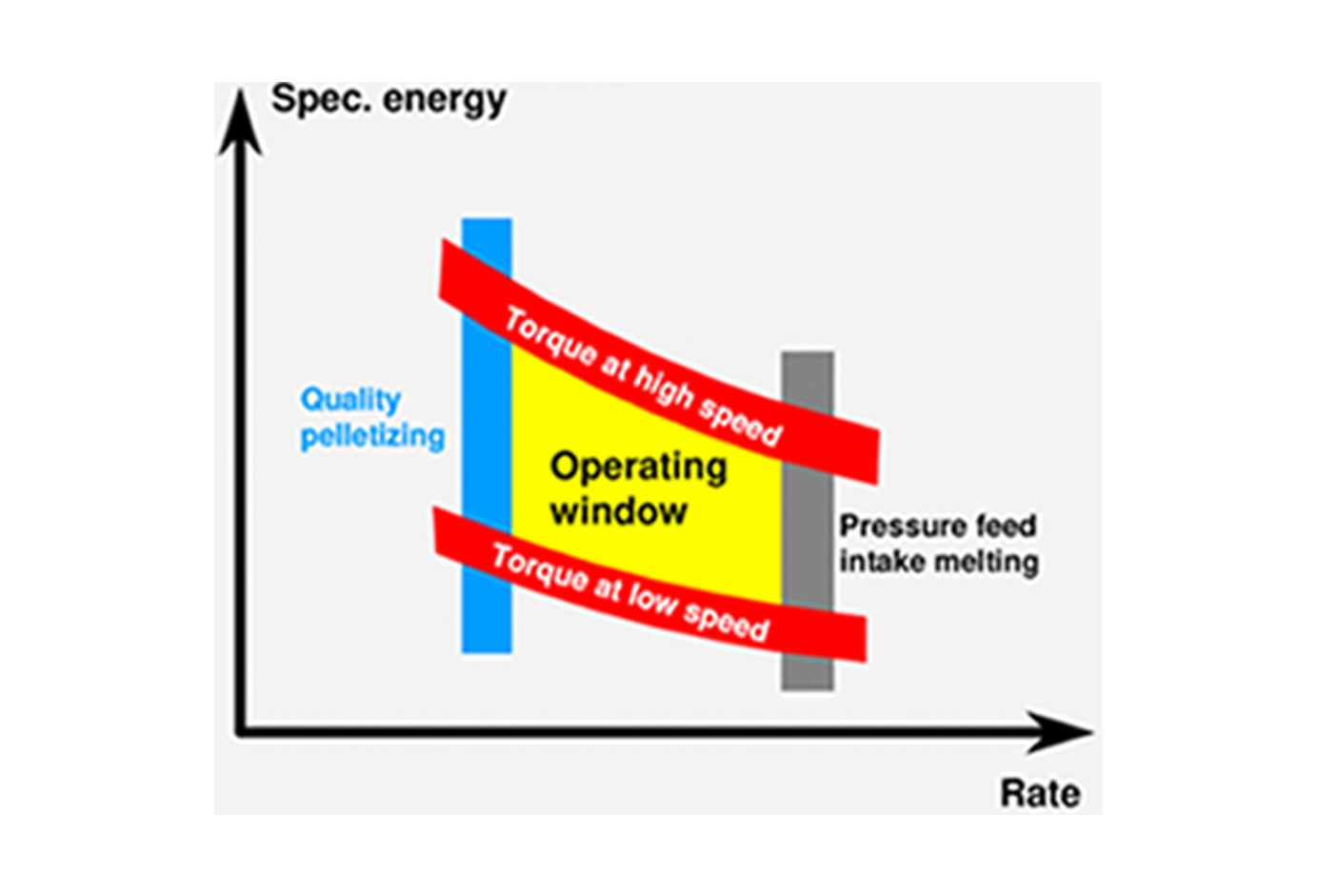

In pharmaceutical formulation development, following the "Quality by Design" (QBD) principle, it is essential to explore the operational space that meets the product's critical quality attributes (CQA). For hot melt extrusion, this operational space depends on the system's torque—the greater the torque, the greater the process window. To meet this need, PPS developed the second-generation PPS TSE16 P hot melt extrusion system, offering a torque of up to 30Nm. This system can handle high-viscosity excipients, avoiding shutdown risks due to torque limits, and provides researchers with sufficient process window to find the best production processes ensuring product CQA.

1.China's first powerful hot melt extrusion system!

2.The highest torque pilot/small-scale production system in China!

3.High torque offers greater formulation/excipient screening possibilities!

Product Features:

1.High torque - 30Nm, can extrude almost all excipients smoothly (such as high-viscosity HPMCAS, PVP K30, etc.);

2.Ultra-P temperature control system: precise temperature control (±1℃);

3.Quick-connect design: easy installation and disassembly, can be cleaned as a whole;

4.Complete upstream (feeder) and downstream (cooling conveyor and pelletizing) equipment;

5.Small footprint: integrated design.

Technical Parameters:

|

PPS TSE Elf |

|||

|

L/D Ratio (L/D) |

30 |

Torque(Nm) |

30 |

|

Diameter (mm) |

16 |

Max. Power(KW) |

2 |

|

Max.Speed(RPM) |

600 |

Output (Kg/h) |

0.02-2 |

*Specific output depends on specific processes and formulations